Brand Story

Since our founding in 1955, we have passed down our skills and passion from generation to generation. At UVUMBRA, we embody the spirit of craftsmanship, creating umbrellas that are not just functional but also warm, beautiful, and emotionally resonant. We are dedicated to continuing our tradition of excellence, crafting umbrellas with sincerity and a commitment to quality. UVUMBRA believes that a great umbrella is more than just a shield against the elements; it is a product that enhances everyday life, bringing joy and comfort to all who use it.

Six and Eight: The Umbrella's Journey

For 69 years, we have been dedicated to the art of umbrella making. Our craft has been passed down from master to apprentice, with each generation refining and perfecting the techniques. This rich tradition has led to the development of the most precise and scientific processes in the industry. With six meticulous crafting steps and eight thorough inspection stages, we ensure that every umbrella we create is perfect. Our commitment to excellence and heritage is at the heart of everything we do, as we continue to honor and advance the legacy of our craft.

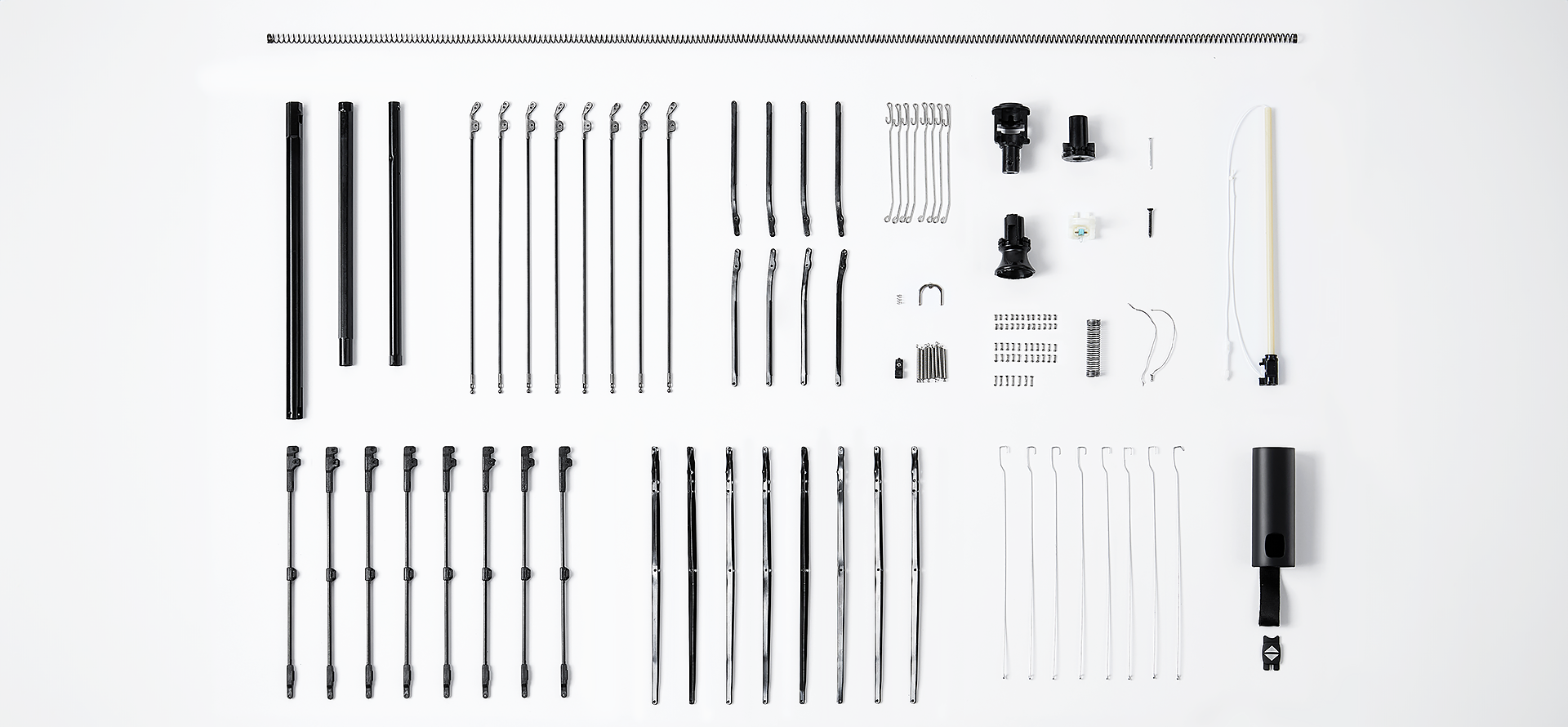

A Symphony of Six

Born from a single fabric and a solitary metal rod, our umbrellas undergo a transformative journey. Six meticulously crafted steps, passed down through generations, shape each umbrella into a symbol of elegance and durability. Every curve, every stitch, and every rivet is a testament to our commitment to perfection.

-

Fabric Cutting

The journey of an umbrella begins with a bolt of fabric. This raw material is meticulously cut into smaller pieces, each precisely measured to fit the specific design of the umbrella. The choice of fabric, from lightweight nylon to durable polyester, greatly influences the final look and feel of the umbrella.

-

Hemming

To enhance durability and prevent fraying, the edges of the fabric pieces are carefully stitched. This process not only strengthens the material but also adds a finished aesthetic to the umbrella.

-

Fabric Inspection

Quality control is paramount in umbrella manufacturing. Each fabric piece undergoes a rigorous inspection to ensure it meets the highest standards. Defects such as holes, stains, or uneven dyeing are carefully scrutinized. This meticulous examination guarantees that only the finest materials are used in the creation of our umbrellas.

-

Cutting Panels

The cut fabric is further divided into panels, which are the individual triangular or rectangular pieces that form the umbrella canopy. The size and shape of these panels vary depending on the desired size and style of the umbrella. Precise cutting ensures that the panels fit together seamlessly, creating a smooth and symmetrical canopy.

-

Panel to Panel

To create a strong and durable canopy, the individual panels are carefully sewn together. This process involves aligning the edges of the panels with precision and stitching them using high-quality thread. The stitching not only joins the panels but also creates a decorative pattern that adds visual interest to the umbrella.

-

Sewing with Frame

The final step involves attaching the completed canopy to the umbrella frame. This intricate process requires skilled craftsmanship and attention to detail. The canopy is carefully sewn to the ribs and center spine of the frame, ensuring a secure and even fit. The choice of stitching and the type of thread used can significantly impact the overall appearance and functionality of the umbrella.

Eight Notes of Quality

The creation of an umbrella is a delicate ballet of art and engineering. Each step of our nine-step inspection process is a brushstroke on the canvas of perfection. From the aesthetic appeal of the design to the functionality of the mechanism, every aspect of our umbrellas is meticulously examined.

-

Light Transmission

The umbrella fabric undergoes rigorous testing to determine its Ultraviolet Protection Factor (UPF) rating. This ensures that the fabric provides adequate protection from harmful UV rays.

-

Abrasion Resistance

The fabric's resistance to abrasion is tested to ensure its durability. This is particularly important for areas that experience frequent contact, such as the tip and edges of the canopy.

-

Waterproof Performance

Our umbrellas are subjected to a series of water resistance tests to ensure they can withstand heavy rain without leaking. This includes spray tests and immersion tests.

-

Fabric Hydrostatic Head

The fabric's hydrostatic head is measured to determine its ability to withstand water pressure. A higher hydrostatic head indicates better waterproofing.

-

Shaft Strength

The umbrella shaft is subjected to a load test to determine its strength and ability to withstand bending and twisting forces.

-

Rib Alignment

The alignment of the ribs is carefully inspected to ensure that the canopy opens and closes smoothly and evenly.

-

Corrosion Resistance of Metal Components

The metal components, such as the shaft, ribs, and tip, are tested for corrosion resistance to ensure long-lasting performance, even in humid environments.

-

Final Inspection

A comprehensive final inspection is conducted to verify that the umbrella meets all quality standards. This includes checking for defects, ensuring proper functioning of all mechanisms, and verifying that the umbrella meets the specified dimensions.